Multi Tool Blades and The Multi-Function Tool

Whether you are a professional or a fond hobbyist, there is no reason you shouldn’t step up your workshop game by investing in something enthusiasts consider the jack of all trades when it comes to power tools, called the oscillating multi tool. While circular saws move in a rotary direction and reciprocating saws make use of a back-and-forth motion, oscillating multi tools, just as the word “oscillating” suggests, exploit a vibrational motion at up to 20,000 oscillations per minute in order to precisely perform jobs at hard-to-reach areas without damaging the material. These devices come with a large variety of multi tool blades suited to perform various tasks. Common multi tool blades include diamond edge blades, sanding pads, scrapers, HSS and HCS blades, carpet hooks etc. which have been dedicated a section in this article in case you are interested in their details. Let us first shed light on the history behind these multi-functional and practical tools.

History of the Oscillating Multi Tool

The origins of the oscillating multi tool can be traced back to the history of an oscillating tool invented in the medical profession in the 1960s, when there was a requirement for a solution that is able to remove plaster casts from a patient’s body without harming the skin and causing acute pain. German electrical engineer and power tool manufacturer, Wilhelm Emil Fein observed that while rotary or reciprocating motions both fulfill the job of removing plaster casts, their trade-off is the fact that they cause cuts in the patient’s body because they penetrate the skin a bit too deep. Utilising an oscillatory motion, however, only caused minor pain while effectively removing the plaster casts. Oscillating tools that we know today make up to 20,000 oscillations at a very small oscillation arc of 3 degrees, which keeps them from harming the patient’s skin. This oscillatory technology proved to be a revolution in the medical sphere. It is still utilised in contemporary medical tools such as those manufactured by Stryker. In the 1980s, Fein came up with the idea of introducing oscillatory technology in the construction industry and invented the first ever oscillating multi tool in 1985, which later paved away for the invention of the MultiMaster. The MultiMaster was designed for the trades industry and targeted a market essentially looking for a tool able to perform multiple tasks efficiently, which was made possible through the introduction of several multi tool blade attachments designed for specific jobs. The oscillating multi tool as we know today is an emblem of Fein’s creative approach towards problems in the medical, construction and trades industries years ago.

A Guide to Various Multi Tool Blades: Uses and Applications

Now that we know the wisdom behind the birth of the multi tool, let us discuss its various attachments and what they are meant for. Oscillating tools perform a variety of tasks such as cutting, grinding, sanding, sawing, rasping, scraping, polishing etc. and this all comes down to the blade attachment you utilise. You can only make the most out of your multi tool if you learn to use the right attachment for the right kind of job, so let us guide you to some of the most common attachments:

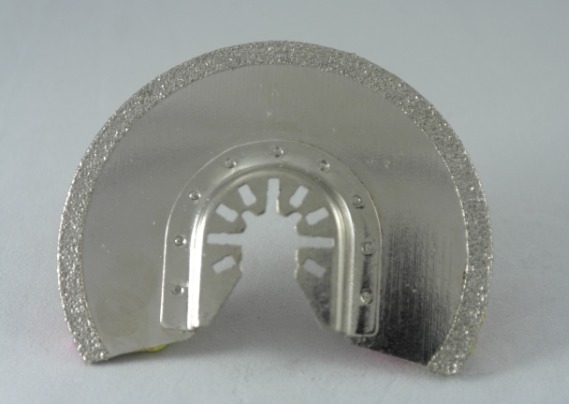

We all know diamond is the hardest material on Earth. The inclusion of a diamond grit in diamond edge blades makes them impact-resistant and renders them the capability to cut through materials like tile and grout efficiently. They might be a bit more on the expensive side, but you will get what you pay for. What makes them more useful than most rotary tools is, not only their strength, but also the fact that they create lesser dust and provide more control to the user.

2) Sanding Pads

There are triangular sanding heads available in the market, some requiring an adapter to allow compatibility with various oscillating multi tool types, while others are universal and will not require any adapter at all. These sanding pads can even out surfaces at very narrow and intricate parts and crevices, something you may not be able to achieve with an electric sander or a hand sandpaper.

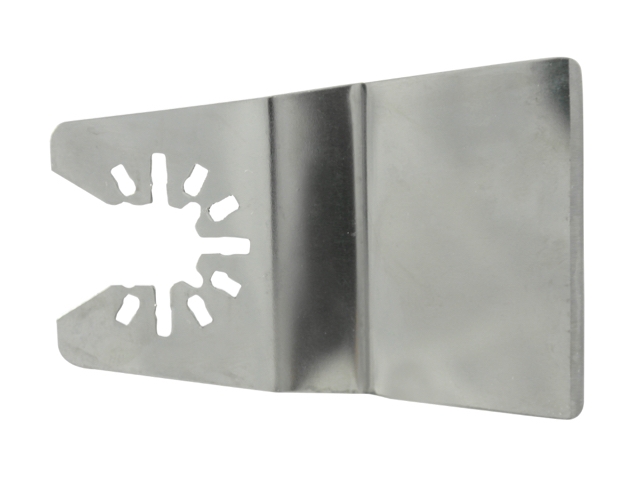

Apart from using as a sander, you can also effectively use your oscillating multi tool as a scraper. In some instances, scraper blades do a much more efficient job than manual scrapers at removing paint, wallpapers or caulk. These blades are available in a variety of widths depending on the desired job. They are classified into two types: rigid and flexible. Rigid scrapers are more suited for scraping off materials like linoleum or glue, while flexible scrapers are used for getting rid of caulk or paint.

4) HSS (High Speed Steel) and Titanium Edge Blades

HSS (High Speed Steel) blades are extremely heat-resistant and durable. They draw their strength from the tempering process that they are gone through. They are mostly suited for heavier-duty jobs such as cutting thin sheet metal, soft copper and PVC pipes, nailed woods, brass, bronze, and plastics. Be aware that multi tool blades are not designed to cut through thick metals, only thin layers of metal. They last longer as compared to HCS blades as they are suited for harsher jobs. Titanium edge blades can cut nail-impregnated woods and are also used in applications like window installations and adjustment works. They may come with one or two adapters to fit most oscillating multi tools.

HCS (High Carbon Steel) blades are comparatively softer than their HSS counterparts, which last five times longer. However, HCS have their own application, which is cutting and penetrating softer materials such as plastics and other non-metallic things. Some of the materials they are used on include softwoods, hardwoods, plywood, and a diverse range of plastics. Plexiglas can also be worked on. HCS blades are, by and large, used in applications involving flush or plunge cuts.

6) Hook Blades

Hook blades feature high carbon steel cutting edges which are practical when it comes to penetrating materials involving carpet and cardboard. They are also used to cut asphalt roof shingles and most fabrics. Hand carpet knives mostly cause a lot of physical strain on the user’s hands when used for longer periods of times, but an oscillating multi tool makes the job more ergonomic and even faster as you can just slice through the carpet without the blade getting stuck anywhere.

7) Segmented Cutting Blades

Segmented cutting blades are characterised by the fact that they do not have any offset of sorts on their teeth, which renders them the ability to make very neat and smooth linear and plunge cuts. Different segmented cutting blades are designed for different materials. They can cut through plastic, PVC, thin metal and so on, depending on their type.

Conclusion

Multi tool blades, by virtue of their versatility, are useful for performing a great number of tasks. It would be rare these days for tradesmen to not own a multi-function tool. They are often a convenience tool that can help with a small task or a big job alike. It is likely that new and more inventive ways will be introduced, with new blades designed and brought onto the market for a great range of tasks. If you are renovating, building, doing a quick repair job or just installing a power point, the multi-function tool is indeed a handy and versatile tool.

Validate your login